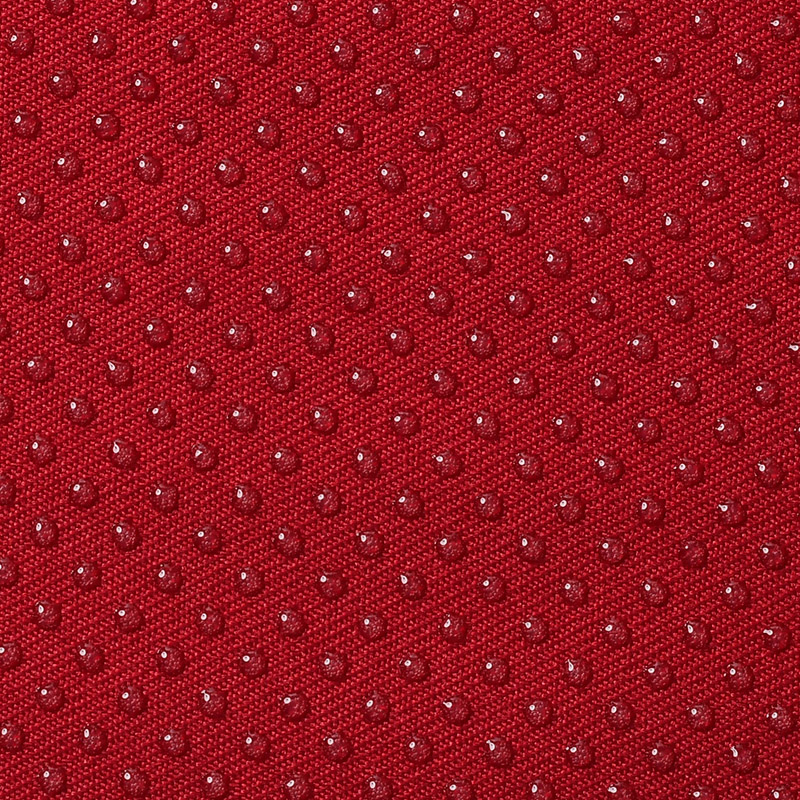

The bonding speed of adhesive tape is one of the important indicators to measure its convenience in practical applications.Dot adhesive tape is usually made of a material with adhesive function,widely used in industries such as electronics,automotive,packaging,etc.,providing stable adhesive performance in various materials and environments.The bonding speed depends on multiple factors,including the composition of the adhesive tape,environmental conditions,and operating methods.Understanding the bonding speed of adhesive tape is crucial for selecting the appropriate adhesive tape product.

1.The relationship between the composition of adhesive tape and bonding speed

The bonding speed of adhesive tape is closely related to its chemical composition and the properties of the adhesive.Common adhesive tapes are composed of hot melt adhesive,pressure-sensitive adhesive,or acrylic adhesive with fast bonding properties.The characteristics of these adhesives directly affect the bonding speed.For example,hot melt adhesive can quickly solidify after heating,usually exhibiting a faster bonding speed;Pressure sensitive adhesives can quickly bond at room temperature without the need for heating or pressing.

2.The influence of environmental factors on bonding speed

Temperature and humidity are the main environmental factors that affect the bonding speed of point adhesive tape.Usually,higher temperatures help with the rapid curing of glue,especially when using hot melt adhesive.Appropriate temperature can significantly improve the bonding speed.For pressure-sensitive adhesives,moderate temperature and low humidity environments typically provide bonding speed.Excessive humidity may cause premature curing or reaction of the adhesive,thereby affecting the bonding speed and effectiveness.

In addition,surface treatment can also affect the bonding speed.If the surface being bonded is uneven or contains impurities such as oil and dust,the bonding speed of the adhesive tape will be significantly affected.A clean surface can facilitate better contact between the adhesive and the surface,thereby accelerating the bonding speed.

3.Operation method and bonding speed

The use of adhesive tape is also closely related to its bonding speed.Usually,adhesive tape is applied to the target surface by manual operation or automatic machine dispensing.During manual operation,the bonding speed may be slow,mainly influenced by the experience of the operators.Ensure that the position and amount of each adhesive are uniform and consistent,thereby improving the overall bonding speed.

For applications that require large-scale production,automated dispensing equipment can significantly improve the bonding speed of adhesive tape.By controlling the dispensing time,dispensing amount,and bonding pressure,fast and adhesive bonding can be achieved.

4.Matching bonding speed with application scenarios

The requirements for bonding speed vary in different application scenarios.In certain situations where rapid production processes are required,such as the assembly of electronic components,rapid bonding is particularly important.Therefore,choosing a point adhesive tape with faster bonding speed(such as pressure-sensitive adhesive or fast curing hot melt adhesive)is crucial.In some scenarios that require fine control and longer curing times,such as art packaging or high-precision equipment installation,good bonding speed may not be necessary,but more emphasis may be placed on the durability and stability of the bonding effect.

5.Other factors affecting bonding speed

In addition to the above factors,the thickness of the adhesive tape,bonding pressure,and curing time of the glue also affect its bonding speed.Usually,thinner adhesive tape requires shorter curing time and faster bonding speed;Thicker adhesive fabrics may require longer curing times.In addition,excessive bonding pressure may cause the glue to solidify prematurely,thereby affecting the bonding speed.

summarize

The bonding speed of adhesive tape not only depends on its own composition and characteristics,but also on external environment and operating methods.When choosing a suitable adhesive cloth,in addition to considering its bonding speed,a comprehensive evaluation should also be conducted based on the actual application requirements.Understanding the bonding speed characteristics of different types of adhesive tape can help users achieve stable bonding effects in different production environments.

If you are looking for related products or have any other questions, you can call our company's sales hotline at 0769-86415161 or 138-2923-0758 at any time. You can also leave us a message below and we will serve you enthusiastically!